Introduction

Cleanrooms are specialized environments where air quality, temperature, and humidity must be strictly controlled to meet industry standards. The Air Handling Unit (AHU) plays a critical role in ensuring contamination control, energy efficiency, and regulatory compliance. Whether in pharmaceuticals, electronics, biotechnology, or healthcare, the design of a Cleanroom AHU must be meticulously planned to maintain precise environmental conditions.

In this blog, we’ll explore:

- Key design considerations for Cleanroom AHUs

- Components and configurations

- Filtration strategies and airflow management

- Energy efficiency and sustainability practices

- Maintenance best practices

1. Key Design Considerations for Cleanroom AHUs

The design of a Cleanroom AHU must align with ISO 14644 standards and industry-specific regulations (such as GMP, FDA, and EU Annex 1). Here are the critical design factors:

1.1 Air Quality & Filtration Efficiency

- Cleanroom AHUs must maintain specific ISO classification levels (e.g., ISO 5, ISO 7, ISO 8).

- High-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filters are required to remove airborne contaminants.

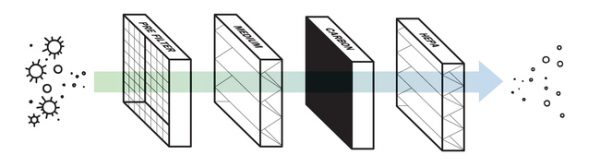

- Multi-stage filtration (Pre-filters → Medium Filters → HEPA/ULPA) ensures optimal air cleanliness.

1.2 Temperature and Humidity Control

- Precision temperature control (+/- 1°C) is required for sensitive manufacturing processes.

- Relative humidity (RH) control (ranging from 40%-60%) prevents electrostatic discharge and microbial growth.

- Dehumidification and humidification systems integrated into AHUs regulate moisture levels.

1.3 Airflow Management

- Laminar airflow (unidirectional flow) is critical for high-class cleanrooms (ISO 5 and below).

- Turbulent airflow is acceptable for lower-class cleanrooms (ISO 7-8).

- Air Changes per Hour (ACH) (Use TheHVACLab ACH Calculator) varies based on the classification:

- ISO 5: 240-600 ACH

- ISO 7: 60-90 ACH

- ISO 8: 20-40 ACH

1.4 Pressure Differentials

- Positive pressure (+10 to +15 Pa) prevents contaminants from entering cleanrooms.

- Negative pressure (-10 to -30 Pa) is required in biohazard labs and pharmaceutical containment zones.

- Airlocks and pressure monitoring sensors ensure proper differential pressure.

1.5 Regulatory Compliance

- Compliance with ISO 14644, FDA, GMP, and EU Annex 1 guidelines is mandatory.

- Cleanroom AHUs must meet ASHRAE 170 standards for healthcare environments.

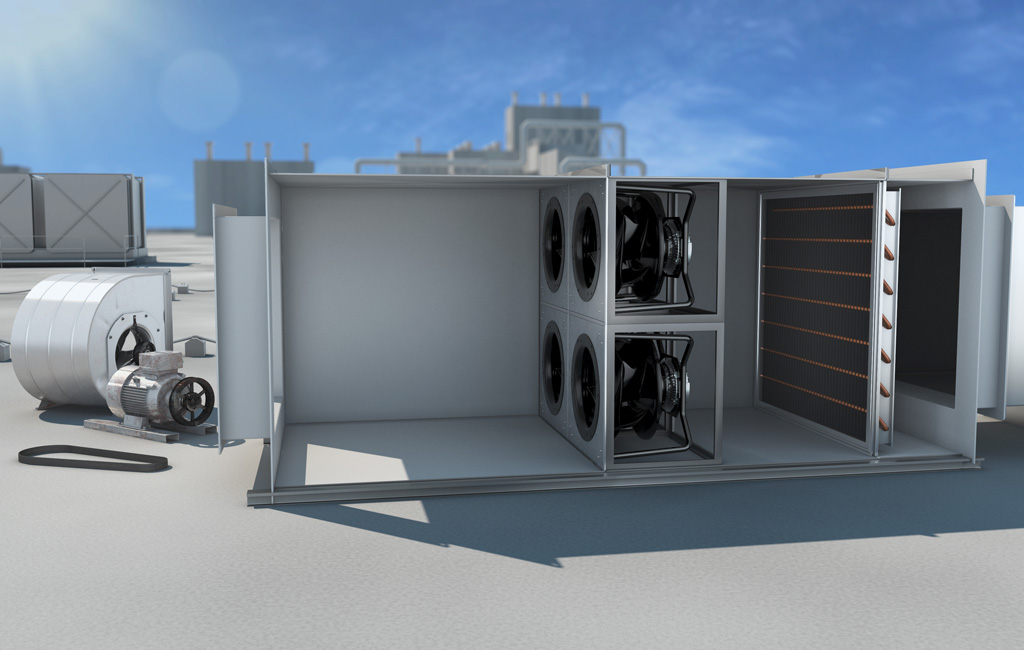

2. Cleanroom AHU Components & Configurations

A well-designed Cleanroom AHU consists of several essential components:

2.1 Filtration System

- Pre-filters: Captures large dust particles and extends the life of HEPA filters.

- Bag/Medium Filters: Removes smaller particulates before HEPA filtration.

- HEPA/ULPA Filters: Final filtration to maintain cleanroom classification.

- Carbon Filters (Optional): Controls odors and VOCs in specialized applications.

2.2 Fan & Motor System

- EC (Electronically Commutated) Fans: Improve efficiency and reduce energy consumption.

- VFD (Variable Frequency Drive): Adjusts airflow based on cleanroom occupancy and load.

- Redundant Fan Systems: Ensures continuous operation in critical applications.

2.3 Temperature & Humidity Control

- Cooling Coils: Chilled water or DX coils for temperature regulation.

- Heating Coils: Steam, electric, or hot water coils for precise temperature control.

- Humidifiers & Dehumidifiers: Ultrasonic or steam-based humidifiers for RH management.

2.4 Airflow Control & Distribution

- Dampers & Louvers: Modulate air distribution and maintain airflow balance.

- Plenum Chambers: Optimize airflow uniformity for laminar flow applications.

- Ductwork Design: Should be smooth and sealed to prevent particle accumulation.

3. Filtration Strategies & Airflow Design

A multi-stage filtration strategy is essential to achieve contamination-free air in cleanrooms.

3.1 Multi-Stage Filtration Approach

| Filter Type | Efficiency | Particle Size |

|---|---|---|

| Pre-Filters | G4 – MERV 8-10 | 10-20 μm |

| Secondary Filters | F7/F9 – MERV 13-16 | 1-10 μm |

| HEPA/ULPA Filters | H13-U17 – MERV 17-20 | 0.3 μm |

| Carbon Filters (Optional) | VOC Absorption | Chemical Fumes |

3.2 Airflow Distribution Techniques

- Laminar Flow Ceilings: Provide uniform downward airflow in critical areas.

- Turbulent Flow for Lower Class Cleanrooms: Ensures efficient mixing of clean air.

- Ceiling & Floor Return Air Grilles: Optimized placement reduces particle buildup.

4. Energy Efficiency & Sustainability in Cleanroom AHUs

Designing an energy-efficient Cleanroom AHU lowers operational costs while maintaining high-performance standards.

- EC Fans & VFDs: Optimize fan speed and power consumption.

- Heat Recovery Wheels: Reclaim energy from exhaust air.

- Advanced Controls & IoT Sensors: Monitor real-time conditions and optimize settings.

- Demand-Based Ventilation: Adjust airflow based on occupancy levels.

- High-Efficiency HEPA Filters: Reduce pressure drop and energy use.

Call-To-Action (CTA)

- Need expert Cleanroom AHU design? Contact us today for a free consultation!

- Stay updated with the latest HVAC trends—subscribe to The HVAC Lab newsletter!

For more insights on HVAC system design and cleanroom technology, stay connected with The HVAC Lab!