“In today’s world, where energy efficiency is a top priority, selecting the right refrigerant for your HVACR system is more crucial than ever. With the ongoing push for sustainable solutions and reduced environmental impact, the choice of refrigerant can significantly influence system performance, operating costs, and your carbon footprint. In this post, we’ll explore how to make informed decisions when selecting energy-efficient refrigerants, ensuring your system is not only effective but also eco-friendly.”

A refrigerant is a chemical substance that serves as the key working fluid in the Vapor Compression Refrigeration System (VCRS) cycle. Selecting a refrigerant requires consideration of several critical factors, including thermophysical properties, chemical stability, flammability, and toxicity. The ASHRAE Standard 34 provides in-depth knowledge about refrigerant classification.

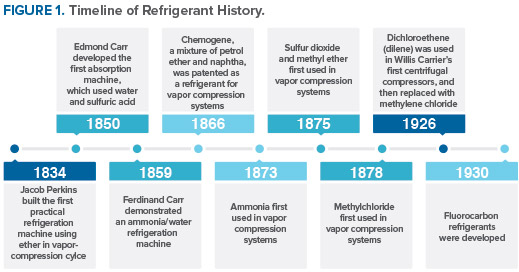

Evolution of Refrigerants

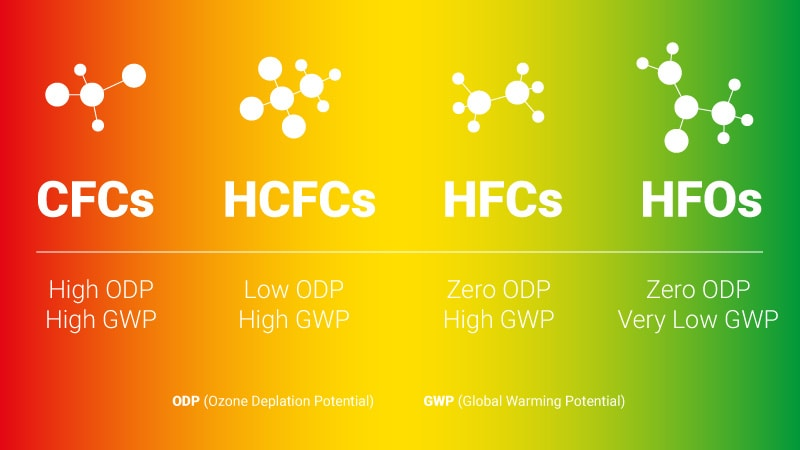

Initially, Chlorofluorocarbon (CFC) refrigerants were widely used. However, these refrigerants were found to damage the stratospheric ozone layer. Subsequently, Hydrochlorofluorocarbons (HCFCs), Hydrofluorocarbons (HFCs), Hydrocarbons (HCs), and Hydrofluoroolefins (HFOs) have been adopted in HVAC systems due to their reduced environmental impact.

Environmental Metrics vs. Refrigerants

The following environmental metrics are crucial when selecting a refrigerant:

- Ozone Depletion Potential (ODP):

Measures a material’s ability to deplete the stratospheric ozone layer, relative to R-11. - Global Warming Potential (GWP):

Assesses a material’s ability to trap heat in the Earth’s atmosphere, contributing to global warming. GWP is measured relative to CO₂, which has a high atmospheric lifetime. - Total Equivalent Warming Index (TEWI):

Represents the sum of direct and indirect emissions associated with HVAC systems.- Direct Emissions: Refrigerant leakage during charging or recovery.

- Indirect Emissions: Emissions related to electricity consumption to operate HVACR systems.

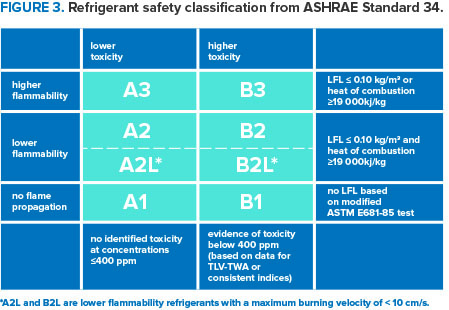

Refrigerant Safety Classification

Refrigerants are classified based on toxicity and flammability as per ASHRAE guidelines:

- Toxicity Classes:

- Class A: Refrigerants with an occupational exposure limit (OEL) of 400 ppm or greater.

- Class B: Refrigerants with an OEL of less than 400 ppm.

- Flammability Classes:

- Class 1: No flame propagation in air at 60°C and 101.3 kPa.

- Class 2: Exhibits flame propagation with lower flammability limits (LFL) > 0.10 kg/m³ at 23°C and 101.3 kPa, and heat of combustion < 19,000 kJ/kg.

- Class 2L: Subset of Class 2 refrigerants with a maximum burning velocity ≤ 100 mm/s.

- Class 3: Highly flammable, with LFL ≤ 0.10 kg/m³ or heat of combustion ≥ 19,000 kJ/kg.

Key Refrigerant Properties

- Thermodynamic Properties:

- Low Boiling Point: Ensures efficient heat absorption at lower temperatures.

- High Critical Temperature: Enables operation at higher condensing temperatures.

- High Latent Heat of Vaporization: Provides efficient heat transfer with smaller refrigerant quantities.

- Low Specific Volume: Reduces compressor size and energy consumption.

- Environmental Impact:

- Low GWP: Minimizes climate change impact.

- Zero or Low ODP: Protects the ozone layer.

- Regulatory Compliance: Meets standards like the Kigali Amendment and EU F-Gas regulations.

- Safety Parameters:

- Non-Flammability: Reduces fire risks (e.g., ASHRAE Class A1 refrigerants).

- Low Toxicity: Ensures safety for occupants and technicians.

- Chemical Stability: Prevents decomposition under normal conditions.

- Material Compatibility:

- Non-Corrosive Nature: Protects system components like pipes and heat exchangers.

- Lubricant Compatibility: Ensures proper compressor operation.

- Economic Factors:

- Cost-Effectiveness: Reduces system operating costs.

- Availability: Ensures easy refilling and maintenance.

- Energy Efficiency: Lowers energy consumption.

- Practical Parameters:

- Good Heat Transfer Coefficient: Enhances heat exchange efficiency.

- Low Pressure Drop: Reduces energy losses.

- Ease of Leak Detection: Facilitates timely maintenance.

Examples of Desirable Refrigerants

- Natural Refrigerants: CO₂ (R744), Ammonia (R717), Propane (R290).

- HFOs: Hydrofluoroolefins like R1234yf (low GWP).

- Blends: R32, R410A (commonly used but higher GWP).

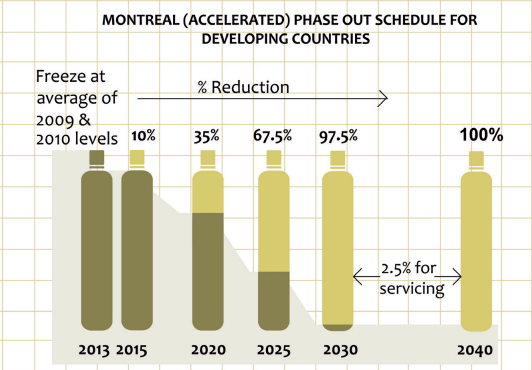

Refrigerant Phaseout Schedule

Refrigerants have significant environmental impacts, prompting international agreements to phase out harmful substances. The Montreal Protocol (1986) initiated this effort, followed by the Kigali Amendment (2015), which targets HFC reduction.

Conclusion

The choice of refrigerant is crucial for system performance and environmental sustainability. This article highlights the key aspects of refrigerants and their properties. For detailed insights, refer to authoritative sources.

References

- ASHRAE Fundamentals Handbook

- HCFC Phaseout and Energy Efficiency in Buildings

- Transitioning HFCs in India

- AHSRAE Standard 34