Controlling fan or pump speed used to be binary: on or off. But with Variable Frequency Drives (VFDs), HVACR systems now operate with precision and energy efficiency. This blog explores the pivotal role of VFDs in HVACR systems, showcasing how they improve operational flexibility, energy efficiency, and system longevity. We’ll cover principles of VFD operation, applications, ASHRAE/ISHRAE standards, real calculations, and implementation strategies.

What is a VFD?

A Variable Frequency Drive (VFD) is a power electronic device that modulates motor speed by adjusting the frequency and voltage supplied to the motor. In HVACR, this enables variable flow operation of fans, pumps, and compressors for improved energy efficiency.

Working Principle of VFDs

VFDs consist of three main components:

- Rectifier: Converts fixed AC supply to DC.

- DC Link: Smoothens and stabilizes DC voltage.

- Inverter: Converts DC back to AC with variable frequency and voltage using pulse width modulation (PWM).

VFD Frequency Modulation Calculations

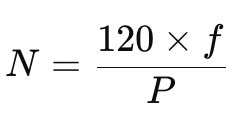

The motor speed (RPM) in a VFD-driven system is directly proportional to the applied frequency:

Where:

- N = Motor speed (RPM)

- f= Frequency (Hz)

- P= Number of poles of the motor

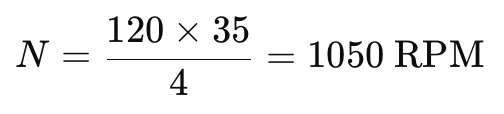

- Speed Control Calculation

- Given:

- 4-pole motor

- Rated frequency = 50 Hz

- VFD operating at 35 Hz

- At 50 Hz:

- Result: The motor now runs at 70% of rated speed (1050 / 1500 = 0.7)

Key Applications of VFDs in HVACR

VFDs in Chilled Water Pumps

- Pumps operate on system differential pressure demand.

- Energy savings of 30–60% achievable using VFDs.

VFDs in Air Handling Units (AHUs)

- Fans controlled by CO₂ levels or duct static pressure.

- Smooth airflow delivery ensures comfort and energy efficiency.

VFDs in Cooling Towers

- Fan speed modulated based on wet bulb temperature.

- Ensures optimal condenser water temperature control.

VFDs in Compressors

- VFDs on screw or scroll compressors improve part-load efficiency.

- Reduces compressor cycling, extends equipment life.

Benefits of VFDs in HVAC

- Dynamic control: Adapt system capacity to real load.

- Energy savings: Especially in part-load conditions.

- Reduced maintenance: Less mechanical wear.

- Soft start/stop: Minimizes electrical and mechanical stress.

- Lower noise levels: Especially in night operation modes.

VFD Control Strategies in HVAC

- Duct Static Pressure Reset

- Return Air Temperature Control

- Delta-T Maintenance in Hydronic Systems

- Discharge Air Pressure Matching

- Occupancy-Based Control via BAS

All strategies align with ASHRAE Guideline 36 and 90.1 recommendations.

Case Study: VFD Retrofit in a Commercial Building

Project: 400 TR HVAC plant in Hyderabad

Action: Retrofitted 3 chilled water pumps and 2 AHUs with VFDs

VFD Energy Savings Calculation Table

| Parameter | Before | After | Units / Notes |

|---|---|---|---|

| Power per Pump | 18 | 8.5 | kW |

| Total Pump Load | 54 | 25.5 | kW (3 pumps) |

| Run Hours / Year | — | 3600 | hrs |

| Energy Use / Year | 194,400 | 91,800 | kWh |

| Energy Saved | — | 102,600 | kWh |

| Cost / kWh | — | ₹8 | INR (India rate) |

| Cost Savings | — | ₹820,800 | ₹ / year |

| VFD Investment | — | ₹600,000 | ₹ (est.) |

| ROI | — | <1.6 Yrs | Payback Period |

Challenges and Considerations

- Harmonics: Use of line reactors or filters recommended.

- Voltage Spikes: Long cable runs require dV/dt filters.

- Compatibility: Motors should be inverter-duty rated.

- Environmental Conditions: Ensure IP-rated enclosures for VFDs in dusty or humid locations.

Summary

- VFDs allow real-time motor speed control by varying frequency.

- Mathematical calculations show cubic energy savings potential.

- Used in pumps, fans, compressors, and cooling towers.

- Compliant with ASHRAE/ISHRAE standards.

- ROI typically <2 years, especially in retrofits.

References

FAQ Section

- How does a VFD save energy in HVAC systems?

By reducing motor speed based on demand, power consumption is reduced cubically—i.e., even a 20% speed reduction can save ~50% energy. - What’s the formula to calculate speed using a VFD?

Speed N=120×f/P, where f is the frequency and P is the number of poles. - Are VFDs suitable for compressors?

Yes, especially for screw and scroll compressors where modulation improves part-load efficiency. - Can VFDs be installed on any HVAC motor?

Only inverter-duty rated motors should be used with VFDs to avoid insulation failure and heating issues. - How can I calculate energy savings from a VFD?

Use Affinity Laws: Power Saved=1−(Speed Reduction)3