Air pollution remains one of the most significant environmental threats to global health, disproportionately affecting children and vulnerable populations. In 2019, an alarming 99% of the global population resided in areas failing to meet WHO air quality guidelines, with ambient and household air pollution collectively contributing to 6.7 million premature deaths annually. Among these, 4.2 million deaths were directly linked to outdoor air pollution, with 89% occurring in low- and middle-income countries, particularly in the WHO South-East Asia and Western Pacific Regions. Addressing this crisis requires targeted policies and investments in cleaner transportation, energy-efficient infrastructure, sustainable power generation, industrial practices, and effective waste management. Additionally, ensuring access to clean household energy in affected regions can significantly reduce pollution levels and improve public health outcomes. This abstract underscores the urgent need for collaborative global action to mitigate air pollution and safeguard human health and the environment.(Source)

Key Factors to Consider When Selecting an AHU Filter

1. Location (City/Region)

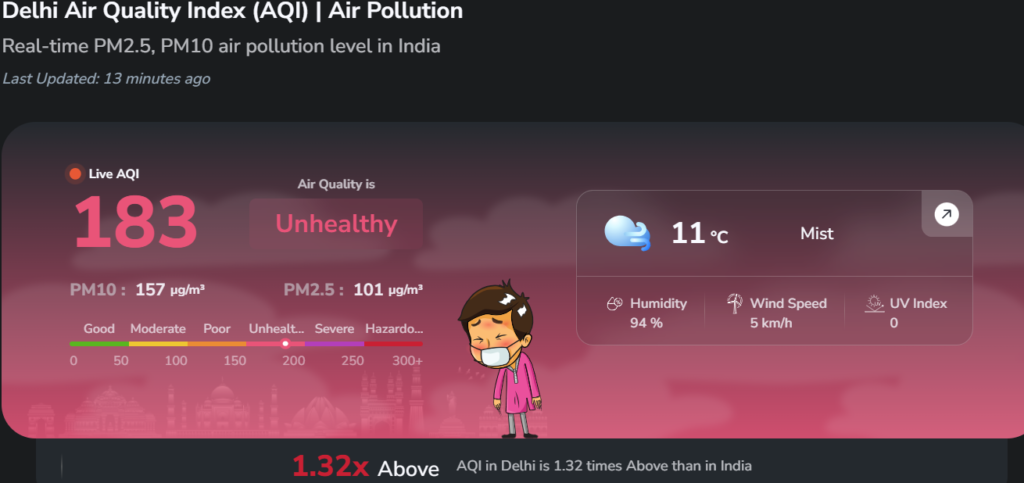

The air quality in your location plays a significant role in determining the right filter. Urban areas are often exposed to high levels of particulate matter (PM2.5 and PM10) due to traffic and industrial emissions. For instance, WHO guidelines suggest PM2.5 levels should not exceed 5 µg/m³ annually, yet cities like Delhi often report levels exceeding 90 µg/m³. In rural areas, the air may have increased organic particles like pollen and dust. Coastal regions face challenges like salt-laden air, which accelerates corrosion of HVAC components and filters. To address these concerns, refer to standards like ISO 16890, which classifies filters based on their efficiency in capturing PM10, PM2.5, and PM1. ASHRAE 62.1 can also guide outdoor air quality considerations in ventilation design.

Live AQI Monitor

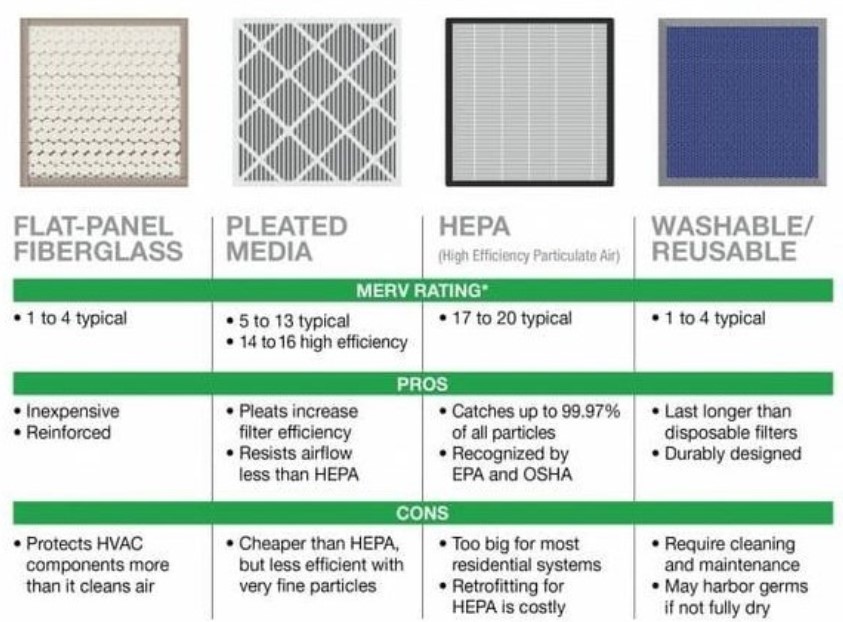

2. Type of Application

The type of application significantly impacts the filtration level required. For dust control in offices, malls, and residential buildings, filters rated MERV 8–13 or ISO ePM10–ePM2.5 are suitable. Industrial plants, airports, and laboratories often require activated carbon filters to capture harmful gases like VOCs, following ASHRAE 145.2 standards for gas-phase filtration. For pathogen control in hospitals, cleanrooms, and pharmaceutical facilities, HEPA filters rated H13–H14, capable of removing 99.97% of particles as small as 0.3 microns, are recommended. WHO guidelines emphasize the use of HEPA filters in healthcare facilities to mitigate airborne diseases like COVID-19 and tuberculosis. Relevant standards include ASHRAE 170 for ventilation in healthcare facilities and EN 1822 for HEPA filter classifications.

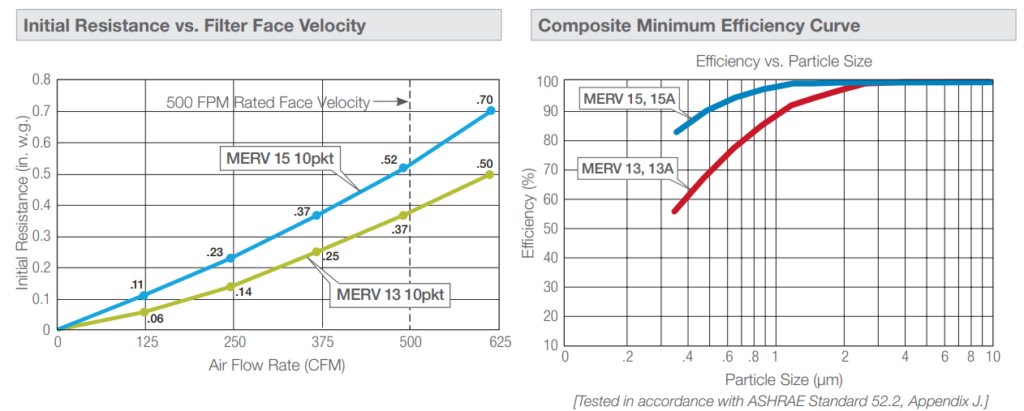

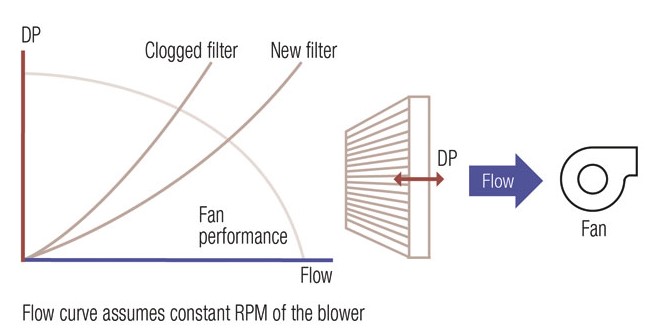

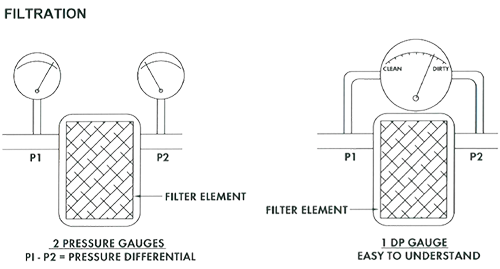

3. Resistance Across the Filter

The pressure drop across a filter affects both energy consumption and system performance. Low-resistance filters save energy but may compromise filtration efficiency, while high-resistance filters provide better filtration at the cost of increased power consumption. According to ASHRAE, higher resistance filters can increase fan energy use by 10–20%, significantly raising operating costs. For commercial applications, it is best to select filters with a pressure drop of ≤125 Pa to balance energy efficiency and filtration performance. Standards like ASHRAE 52.2, which includes MERV ratings and pressure drop values, can guide this selection.

4. Filter Material

The material of the filter determines its durability, efficiency, and suitability for specific applications. Glass wool is commonly used in HEPA filters for pathogen control, while synthetic fibers are durable and suitable for general-purpose applications. Activated carbon filters are effective in removing odors and gases. Poor indoor air quality caused by VOCs and particulate matter contributes to 4.3 million deaths annually, highlighting the importance of effective filtration materials. Standards such as ISO 16890 and EN 779 can be used to evaluate material efficiency.

5. Serviceability

Ease of maintenance is critical for ensuring sustained filter performance. Filters with longer service lives reduce the frequency of maintenance, and AHUs with easy-access panels simplify the replacement process. Additionally, the availability of spare parts and local support is essential. ASHRAE recommends regular filter maintenance to meet indoor air quality standards and minimize energy costs. Filters with replacement indicators can further streamline maintenance schedules.

Case Studies

An office building in Mumbai switched to MERV 13 filters, reducing PM2.5 levels by 85%, which significantly improved occupant productivity. Similarly, a hospital in Chennai upgraded to HEPA H14 filters, decreasing airborne pathogen levels by 98%, aligning with WHO guidelines for healthcare indoor air quality.

FAQs

- How often should filters be replaced? Typically every 3–6 months, depending on usage and air quality.

- Can filters be reused? Most filters are disposable, but washable pre-filters can extend their life.

- What’s the trade-off between efficiency and cost? Higher efficiency filters cost more but save energy and improve IAQ.

Conclusion

Selecting the right air filter for your HVAC system is more than just a technical decision—it’s an investment in health, comfort, and energy efficiency. Whether you’re managing a residential, commercial, clean room, or hospital environment, the right filter can make all the difference in maintaining Indoor Air Quality (IAQ) and reducing long-term operational costs. By understanding your unique needs and following industry standards, you can ensure that your system performs at its best, creating a healthier, more comfortable space for all. Don’t wait—make the right choice today and breathe easy tomorrow!