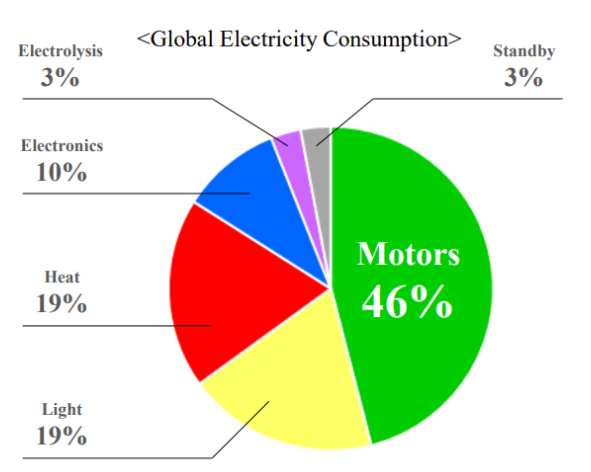

Did you know that electrical motors in the HVACR industry are responsible for consuming nearly 50% of the total electricity in industrial and commercial applications? From powering compressors in refrigeration systems to driving blowers and pumps in air handling units, these motors are the unsung heroes behind the comfort and efficiency of modern climate control systems. However, their energy appetite often goes unnoticed, silently contributing to escalating operational costs and carbon emissions. Understanding how these motors work, selecting the right specifications, and optimizing their performance can unlock significant savings and pave the way for a greener future. Let’s dive into the world of HVACR motors and discover how they shape energy consumption, one kilowatt at a time!

What is an Electrical Motor?

Think of an electrical motor as the heart of your HVAC system. Just as your heart pumps blood, motors convert electrical energy into mechanical energy to drive essential components. Whether it’s spinning a fan or running a compressor, the motor’s efficiency determines how much energy you’re consuming—and paying for.

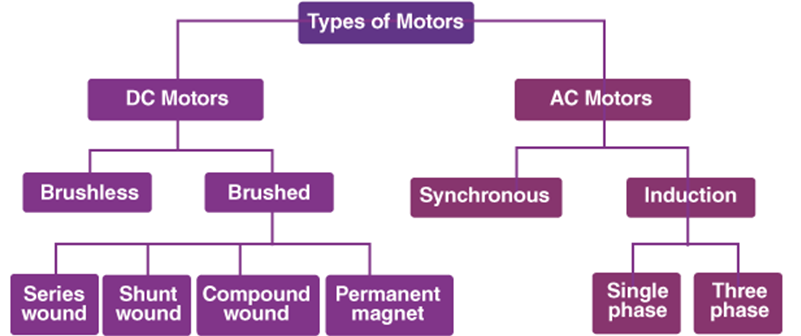

Types of Electrical Motors

Not all motors are created equal. Here’s a quick guide to the main types and where they shine:

- AC Motors:

- Induction Motors: The workhorse of HVAC systems, known for durability and cost-effectiveness. Ideal for compressors and fans.

- Synchronous Motors: Precise and efficient, often used in high-performance systems where exact speed control is critical.

- DC Motors:

- Brushless Motors: Perfect for variable-speed applications like modern air handlers. They’re quiet, efficient, and low-maintenance.

- Brushed Motors: Less common in HVAC due to higher maintenance needs.

- Variable Speed Motors: These are game-changers for energy savings. They adjust their speed based on demand, reducing unnecessary energy use.

Real-World Tip: When upgrading an old HVAC system, consider replacing fixed-speed motors with variable-speed options. It’s an investment that pays off quickly in energy savings.

Motors by Application

- Compressors: Go for robust induction motors that can handle high torque demands.

- Fans and Blowers: Variable speed motors are ideal for optimizing airflow while cutting energy costs.

- Pumps: Synchronous motors offer precise control for liquid circulation, ensuring system efficiency.

Practical Insight: For large commercial buildings, energy-efficient fan motors can reduce HVAC electricity costs by up to 30% annually.

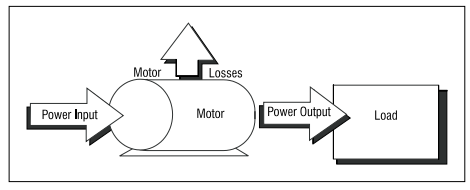

Here’s a simplified diagram of motor energy flow:

- Input Power (kW): Supplied from the grid.

- Losses:

- Copper Losses

- Iron Losses

- Mechanical Losses

- Stray Losses

- Output Power (kW): Useful mechanical energy delivered.

Pro Tip: Regular maintenance, such as lubricating bearings and cleaning air vents, can minimize these losses and improve motor life.

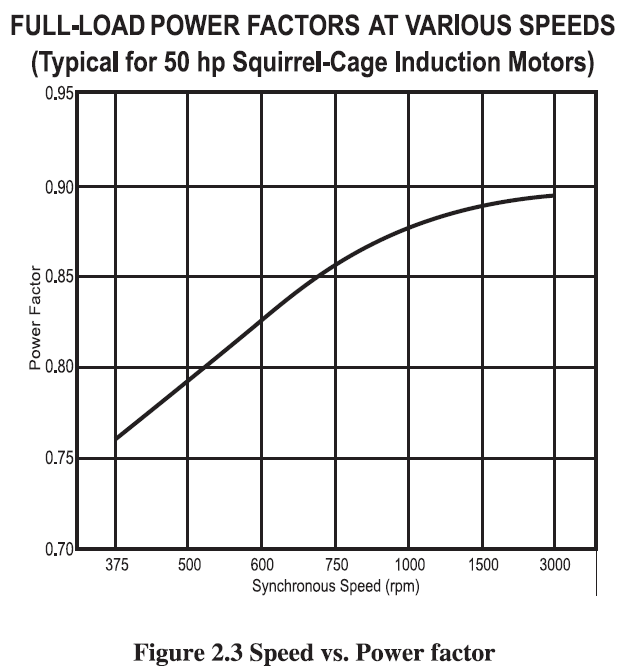

Performance Factors

- Efficiency: A high-efficiency motor turns more electricity into useful work, saving money. Look for motors with IE3 or NEMA Premium ratings.

- Power Factor: A higher power factor means less energy wastage. Installing capacitors can help improve it.

- Operating Conditions: Motors running at extreme temperatures or dusty environments wear out faster. Ensure proper ventilation and protective enclosures.

How to Select the Right Motor

- Understand Your Load: Know the torque and speed requirements of your application. For example, oversized motors waste energy, while undersized ones overheat.

- Match the Environment: Choose motors with appropriate insulation for humid or dusty areas.

- Evaluate Energy Ratings: High-efficiency motors may cost more upfront but save thousands over their lifetime.

- Plan for Flexibility: Variable speed motors adapt to changing demands, making them a versatile choice.

Case Study: A retail mall replaced its fixed-speed fan motors with variable-speed models. The result? A 25% reduction in annual energy costs and improved indoor air quality.

What is an Energy-Efficient Motor?

Energy-efficient motors are designed to do more with less. They use superior materials and advanced designs to reduce energy losses. For instance:

- Improved Windings: Reduce copper losses.

- Better Bearings: Minimize mechanical friction.

Real-World Example: Switching to energy-efficient motors in a medium-sized office building can cut HVAC-related electricity costs by 15-20%.

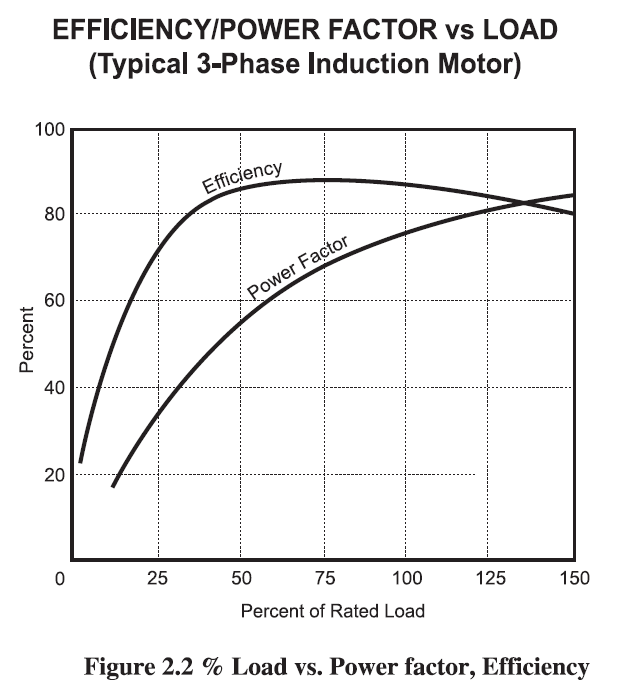

What is Loading?

Loading is how much of a motor’s capacity you’re using. Motors perform best when operating between 50% and 100% of their rated load. Underloading leads to inefficiencies, while overloading risks overheating and failure.

Tip for Engineers: Use load analyzers to measure motor performance in real-time. This helps identify underperforming motors that need replacement or adjustment.

What are Efficiency and Power Factor?

- Efficiency: The percentage of input power converted to output power. Higher efficiency equals lower electricity bills.

- Power Factor: Measures how effectively electrical power is converted into useful work. Low power factor can lead to penalties from utility companies.

Quick Fix: Install power factor correction devices to avoid these penalties and improve overall system efficiency.

Case Study : Energy , Cost , & Emission Savings !

| S. No | Parameters | Case-1(IE2 Motors) | Case-2(IE-3 Motors) | Savings |

| 1 | Number of Motors | 30 | 30 | – |

| 2 | Motor Power (kW) | 30 | 30 | – |

| 3 | Average Loading (%) | 74% | 74% | – |

| 4 | Efficiency (%) | 88% | 95% | – |

| 5 | Power Consumption per Motor (kW) | 25.23 | 23.37 | 1.86 |

| 6 | Total Power Consumption (kW) | 756.82 | 701.1 | 55.77 |

| 7 | Operating Hrs. | 3000 | 3000 | 3000 |

| 8 | Annual Energy Consumption (kWh) | 2,270,455 | 2,103,158 | 167,297 |

| 9 | Energy Cost (Rs./kWh) | 10 | 10 | 10 |

| 10 | Annual Cost (Rs.) | 22,704,545 | 21,031,579 | 1,672,967 |

| 11 | CO₂ Emission Factor (kg/kWh) | 0.85 | 0.85 | 0.85 |

| 12 | Annual CO₂ Emission (kg) | 1,929,886 | 1,787,684 | 142,202 |

| 13 | Annual CO₂ Emission (tons) | 1929.9 | 1787.7 | 142.2 |

Conclusion

Electrical motors are the backbone of HVAC systems, and their performance directly affects energy consumption and operational costs. By understanding motor types, applications, and performance factors, you can make informed decisions that save money and energy. Whether it’s selecting a variable-speed motor or upgrading to energy-efficient models, small changes can lead to big savings—both for your wallet and the environment.

References:

- NEMA Standards Publication MG -2009.

- Bureau of Energy Efficiency (BEE) Guidelines.

- ASHRAE Handbook—HVAC Systems and Equipment.

- WEG-motors-specification-of-electric-motors

- How to determine motor Load & Efficiency