Accurate heat load estimation is critical for the efficient design of cold storage refrigeration systems. Misjudging these loads can lead to oversized systems, increased energy costs, or worse—product spoilage.

This blog dissects the typical heat load components in cold storage facilities and provides a step-by-step example to help HVAC engineers size refrigeration systems correctly.

We’ll cover:

- Types of heat loads

- Design considerations

- Example calculation based on ASHRAE guidelines

Overview of Heat Loads in Cold Storage

Importance of Accurate Load Estimation

In cold storage, even small errors in heat load estimation can result in oversized compressors or undercooled storage, leading to increased operational costs or product degradation.

ASHRAE & ISHRAE Guidelines

ASHRAE Handbook—Refrigeration and ISHRAE Design Guide for Cold Chain recommend segregating loads into distinct categories to avoid oversimplification.

Major Heat Load Sources

Product Load

Definition: Heat introduced by stored products due to temperature difference and respiration (in perishables).

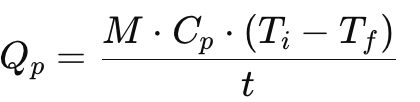

Formula:

Where:

- Qp = product load (kW)

- M = mass of product (kg)

- Cp = specific heat (kJ/kg·K)

- Ti= = initial temp (°C)

- Tf= final temp (°C)

- t= cooling time (s)

Transmission Load

Heat transferred through walls, ceiling, and floor due to ambient temperature.

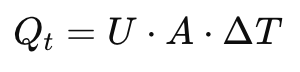

Formula:

Where:

- U= overall heat transfer coefficient (W/m²·K)

- A = area (m²)

- ΔT = temperature difference (K)

Infiltration Load

Caused by air leakage when doors open, or imperfect sealing.

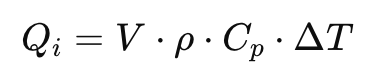

Formula (empirical):

Where:

- V = air volume leakage (m³/s)

- ρ = air density (kg/m³)

- Cp= specific heat of air (kJ/kg·K)

Internal Load

Includes lighting, personnel, and equipment operation.

Approximation:

- Lighting: ~10 W/m²

- People: ~400–600 W per person

- Motors/fans: Rated kW × operating factor

Defrost and Miscellaneous Loads

Defrost heaters, evaporator fans, and compressor inefficiencies add non-negligible loads.

Example Heat Load Calculation

Assumptions:

- Cold room size: 10m × 8m × 4m

- Product: 10,000 kg of apples (Cp = 3.6 kJ/kg·K)

- Entry temp: 25°C, final temp: 2°C

- Cooling time: 24 hours

- Ambient temp: 35°C, cold room temp: 2°C

- Wall U-value: 0.35 W/m²·K

- Door opens: 20 times/day, 30 sec each

Heat Load Components

| Component | Details / Formula | Load (kW) |

|---|

| Product Load | =(10000 x 3.6 x 23) / (24 x 3600) | 9.58 kW |

| Transmission Load | Area = 2 (walls ) + 2 ceiling + floor | 3.51 kW |

| Infiltration Load | Based on ASHRAE air exchange (20 door openings/day, 30 sec each) | 1.8 kW |

| Internal Load | Lighting: 0.8 Personnel: 0.5 Forklift: 1.5 | 2.8 kW |

| Respiration Load | 10,000⋅0.025 (W/kg at 2°C for apples) | 0.25 kW |

| Misc/Defrost Load | Estimated for small cold rooms | 1.2 kW |

| Total Load | Sum of all above components | 19.14 kW |

Design Considerations for Load Reduction

Insulation Strategies

- Use PIR panels or high-density EPS for lower U-values.

- Floor insulation prevents subsoil heat gain.

Door Management

- Install air curtains, PVC strip doors, or rapid roll doors.

- Limit access frequency via automation.

Equipment Sizing

- Oversizing leads to short-cycling.

- Use safety factor ~10% max after total load estimation.

Summary

- Cold storage heat loads include product, transmission, infiltration, internal, and defrost.

- Accurate calculations are vital for energy-efficient design.

- ASHRAE standards guide load separation and estimation.

- Example showed a 19.14 kW load for a small cold room with apples.

References

- ASHRAE Handbook – Refrigeration

- Cold Chain Management – FAO

- U.S. Department of Energy – Energy Efficiency in Cold Storage

FAQ Section

- What is the most significant heat load in cold storage?

Transmission and infiltration are typically the largest contributors, especially in larger or frequently accessed facilities. - How can infiltration heat gain be minimized?

Use air curtains, rapid doors, and limit door opening frequency. - Is defrost load always necessary in heat load calculations?

Yes, especially in humid environments where frost accumulation is common. - What is a typical safety factor in cold storage heat load design?

Generally 5–10% to accommodate unforeseen variables. - How does product type affect heat load?

Specific heat, respiration, and entry temperature all influence the required cooling capacity.