Cooling towers are crucial for commercial, industrial, and HVAC systems, helping remove heat efficiently. Proper maintenance doesn’t just enhance performance—it significantly cuts energy costs and extends equipment life. This guide provides essential cooling tower maintenance tips, expert insights, and real-world solutions.

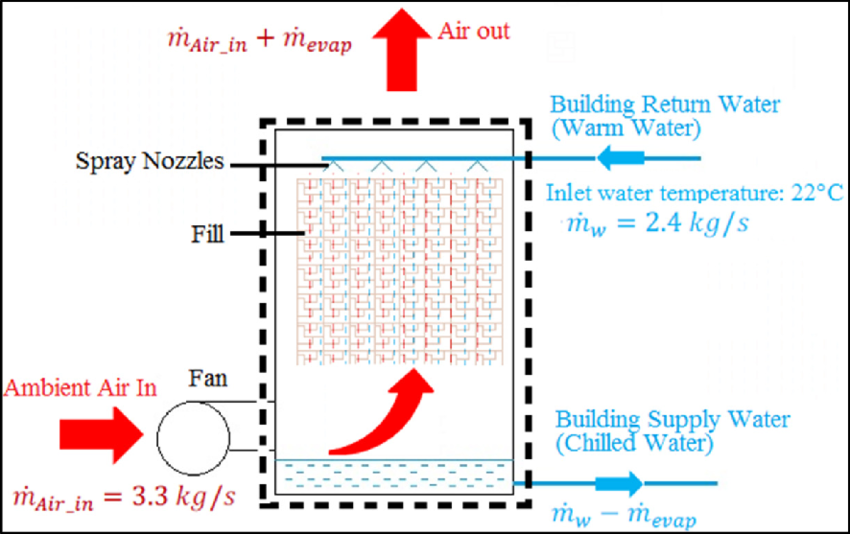

What is a Cooling Tower?

A cooling tower removes heat from water through evaporation, cooling it down before reusing it in various processes. Regular maintenance ensures optimal operation, directly impacting energy efficiency and savings.

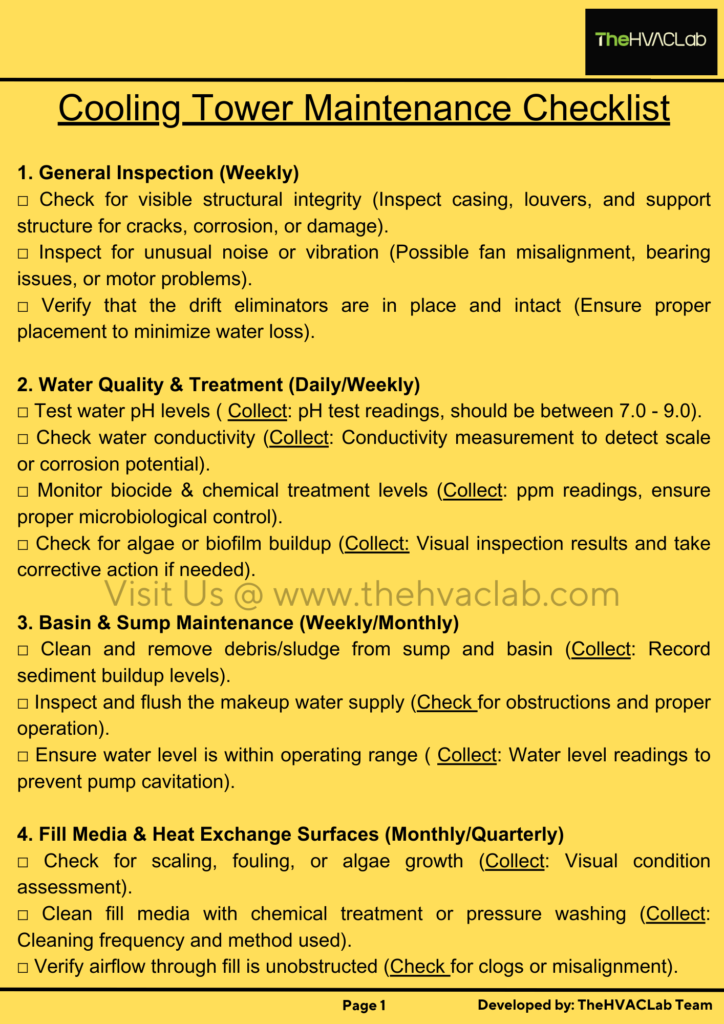

Preventive Maintenance Essentials

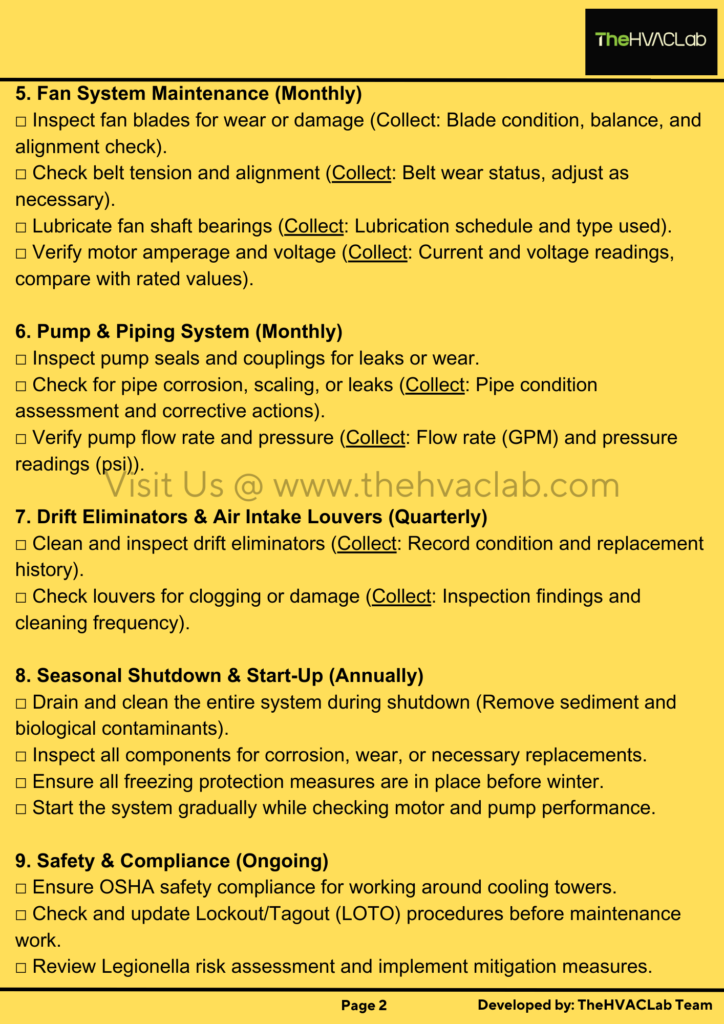

- Routine Inspections: Regularly inspect motors, fans, belts, bearings, and other critical components to identify early signs of wear and avoid costly repairs.

- Keep Fill Media Clean: Regularly clean fill media to maintain efficient heat transfer and prevent clogs that reduce efficiency.

- Effective Water Treatment: Control water chemistry to prevent scale, corrosion, and biological buildup, ensuring efficient cooling tower operation.

- Fan Blade Alignment: Regularly check and adjust fan blade alignment and pitch to optimize airflow and reduce energy consumption.

- Lubricate Moving Parts: Consistent lubrication minimizes friction, reduces energy waste, and prevents premature wear.

Seasonal Maintenance Recommendations

- Summer: Frequently monitor water levels, regularly clean air intake areas, and ensure fans operate efficiently during peak cooling seasons.

- Monsoon: Increase inspection frequency to manage algae and microbial growth effectively.

- Winter: Insulate exposed pipes and components to prevent freezing and potential damage.

Innovative Energy-Saving Solutions

- Install Variable Frequency Drives (VFDs): Adjust fan speeds automatically according to cooling requirements, significantly cutting unnecessary energy use.

- Real-Time Monitoring (IoT): Employ IoT-based monitoring systems to detect and rectify inefficiencies promptly.

- Automated Chemical Treatment: Use precise automated dosing systems for chemical treatment, improving efficiency and reducing environmental impacts.

Real-Life Impact of Preventive Maintenance

Businesses adopting regular preventive maintenance experience energy savings of approximately 20-30%, lower operational expenses, and longer equipment life.

Cost-Benefit Analysis

Preventive maintenance reduces total operating costs by avoiding expensive emergency repairs, minimizing downtime, and ensuring sustained high performance.

Common Cooling Tower Issues & Troubleshooting

- High Energy Consumption: Usually indicates dirty fill media or inefficient fan operation—regularly inspect and clean these areas.

- Poor Water Quality: Adjust water treatment practices to combat biological and scale buildup effectively.

- Noise/Vibration: Often signals misaligned or loose parts needing immediate attention.

Environmental and Compliance Benefits

Effective maintenance aligns your operations with ASHRAE and BEE standards, promoting sustainability and regulatory compliance.

Frequently Asked Questions (FAQs)

Q1: How often should cooling tower maintenance be performed?

Perform basic inspections monthly, detailed checks quarterly, and comprehensive servicing annually.

Q2: Can preventive maintenance reduce electricity bills?

Yes, preventive maintenance significantly reduces energy consumption, directly lowering electricity bills.

Q3: What happens if cooling towers aren’t maintained regularly?

Neglect leads to reduced efficiency, higher energy costs, shortened equipment lifespan, and potential regulatory non-compliance.

Q4: What are best practices for cooling tower water treatment?

Regular testing, chemical dosing, controlling scale, corrosion, and biological growth are critical.

Implementing these comprehensive maintenance practices ensures your cooling towers run efficiently, cuts energy costs, and promotes sustainability.

Stay proactive, save energy, and achieve long-term efficiency.