Introduction

In HVAC energy auditing, air filters are always the first internal component inspected and for good reason. Despite being low-cost items, HVAC filters have a direct and measurable impact on fan energy consumption, indoor air quality (IAQ), and overall system efficiency.

Based on extensive field experience, one issue repeatedly appears across commercial buildings and hospitals: filters are allowed to operate in dirty or clogged conditions for long periods, silently increasing fan power consumption and operating cost.

This article explains:

- How dirty HVAC filters increase energy consumption

- The relationship between filter pressure drop and fan power

- A real, fully verified energy calculation example

- Why filter replacement delivers one of the fastest paybacks in HVAC energy audits

Why HVAC Filters Are Critical in Energy Auditing

During HVAC energy audits, filters are examined first because they directly influence:

- Airflow resistance

- Fan static pressure

- Specific Fan Power (SFP)

- Indoor Air Quality (IAQ)

- Fan and motor loading

A clean filter allows the fan to operate at its design duty point. A dirty filter increases resistance, forcing the fan to consume more electrical energy every hour the system runs.

In facilities operating 24×7—such as hospitals—this becomes a significant hidden energy loss.

Consequences of Dirty or Clogged HVAC Filters

1. Increased Fan Power Consumption

As dust accumulates, filter pressure drop increases. To maintain airflow, the fan must overcome higher static pressure, resulting in:

- Increased fan motor kW

- Higher electrical energy consumption

- Reduced overall HVAC efficiency

Even a moderate increase in filter pressure drop can cause thousands of kilowatt-hours of additional energy use annually.

2. Poor Indoor Air Quality (IAQ)

Dirty filters:

- Lose filtration efficiency

- Allow particle bypass

- Can re-entrain accumulated contaminants

In critical applications such as hospitals, degraded IAQ affects:

- Patient safety

- Infection control

- Compliance with ventilation standards

3. Reduced Airflow to Occupied Spaces

Excessive filter resistance restricts airflow, leading to:

- Hot or cold complaints

- Inadequate ventilation rates

- Increased cooling or reheat demand

This often results in unnecessary control adjustments, further increasing energy consumption.

Filter Cost vs Fan Energy

Filters are inexpensive, but fans are one of the largest energy consumers in HVAC systems. The correct comparison is not filter cost alone, but filter cost versus fan energy penalty caused by high pressure drop.

Actual Energy Calculation Example

Application: Hospital HVAC System – Delhi

This example represents a typical hospital AHU operating in a high-dust urban environment.

| Parameter | Value |

|---|---|

| Design Airflow | 10,000 CFM |

| Operating Schedule | 24 × 7 |

| Annual Operating Hours | 8,400 hours |

| Filtration | Pre-filter + Fine filter |

| Filter Size | 2’ × 2’ |

| Quantity | 5 Nos |

| Fan Type | Centrifugal |

| Fan Efficiency | 65% |

| Motor Efficiency | 90% |

| Electricity Cost | ₹8 / kWh |

Airflow conversion:

10,000 CFM = 4.72 m³/s

Fan Power Formula Used

Where:

Q = Airflow (m³/s)

ΔP = Total static pressure (Pa)

Case 1: Clean / New HVAC Filters

- Clean filter pressure drop = 120 Pa

- Total system static pressure = 800 Pa

Fan Power:

(4.72×800) / (0.65 x 0.90) = 6.45 kW

Annual Energy Consumption:

6.45 kW × 8,400 hrs =54,180 kWh/year

Case 2: Dirty HVAC Filters (After ~1 Year)

- Dirty filter pressure drop = 250 Pa

- Increase in pressure drop = 130 Pa

- Revised static pressure = 930 Pa

Fan Power:

(4.72× 930 ) / (0.65 x 0.90) = 7.50 kW

Annual Energy Consumption:

6.45 kW × 8,400 hrs = 63,000 kWh/year

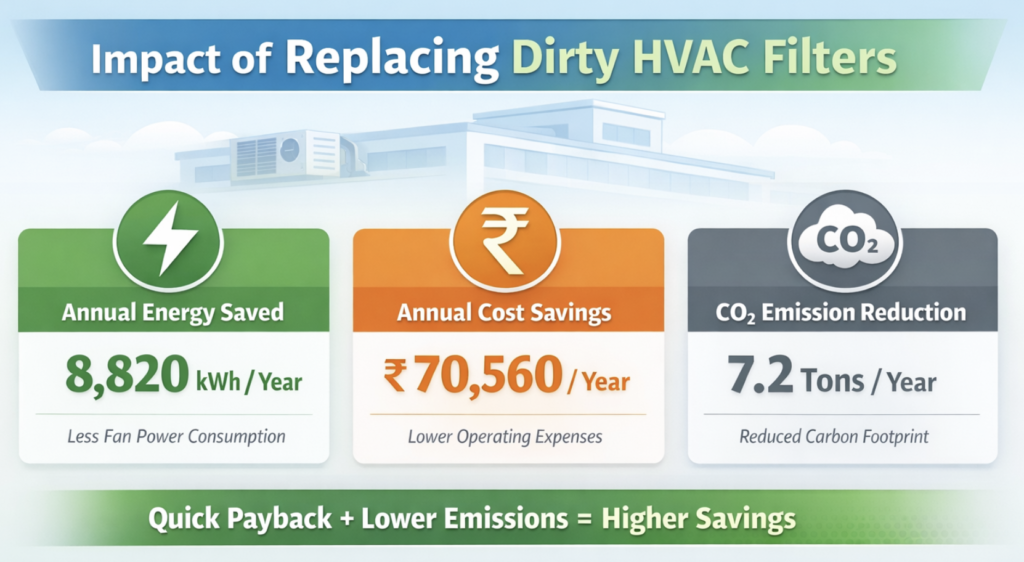

Additional Energy Due to Dirty Filters

| Parameter | Value |

|---|---|

| Increase in Fan Power | 1.05 kW |

| Additional Annual Energy | 8,820 kWh |

| Additional Annual Cost | ₹70,560 / year |

This energy penalty occurs continuously, as long as the filters remain dirty.

Filter Replacement Cost vs Energy Waste

Annual Filter Cost

| Item | Cost |

|---|---|

| Pre-filter + Fine filter (5 Nos) | ₹18,000 |

| Replacement Frequency | Once per year |

Financial Comparison

| Item | Cost |

|---|---|

| Annual Filter Replacement Cost | ₹18,000 |

| Annual Energy Waste | ₹70,560 |

| Net Annual Savings | ₹52,560 |

Simple Payback Period

₹18,000 / ₹70,560 =0.26 years ≈ 3 months

All calculations shown are indicative. Actual energy savings will vary depending on system configuration, operating hours, and site conditions.

What If Filters Are Washed Instead of Replaced?

In many facilities, washable filters are reused after cleaning. However, field measurements show:

- Post-wash pressure drop remains 180–200 Pa

- Fan continues operating above design load

- Partial energy penalty persists

Washing may reduce cost temporarily but does not eliminate energy loss.

Impact on Specific Fan Power (SFP)

Dirty filters directly increase Specific Fan Power (W/CFM), pushing systems beyond recommended efficiency limits defined in ASHRAE guidelines.

Higher SFP results in:

- Poor HVAC energy performance

- Higher operating cost

- Lower energy audit scores

Best Practices for HVAC Filter Energy Optimization

- Replace filters based on pressure drop, not just time

- Monitor filter ΔP during energy audits

- Limit washable filter reuse cycles

- Always include filters when calculating fan energy savings

Frequently Asked Questions (FAQ)

How do dirty HVAC filters increase energy consumption?

Dirty filters increase static pressure, forcing fans to consume more electrical power to maintain airflow.

Are HVAC filters a high-return energy conservation measure?

Yes. Filter replacement often delivers payback in less than 3–4 months in 24×7 systems.

Should filters be replaced or washed?

Replacement is usually more energy-efficient. Washing often leaves residual pressure drop.

Why are filters critical in hospitals?

Hospitals operate continuously and require high IAQ, making filter condition critical for both energy and health.

Call to Action

If you manage HVAC systems or want to do energy audits for your facility reach out us. A simple filter replacement could be your next major energy saving opportunity.

Follow us for more HVAC energy efficiency insights