What if the difference between juicy, tender meat and a dry, freezer-burned product came down to just a few hours?

That’s the power of blast freezing—a high-speed, low-temperature method that locks in quality and keeps food safe. For HVAC professionals and food plant engineers, it’s a critical part of modern cold chain infrastructure.

In this blog, we’ll break down why blast freezing matters, how it works, and how to design systems that meet ASHRAE standards and keep operations efficient.

What is Blast Freezing?

Blast freezing is the process of rapidly cooling meat to -18°C or below using high-speed, low-temperature air. The aim is to pass through the “danger zone” (5°C to -1°C) quickly to prevent microbial growth and maintain cellular integrity.

Key Specs:

- Air Temp: -35°C to -40°C

- Air Velocity: 2.5 to 5.0 m/s

- Freezing Time: Under 4 hours to reach -18°C core

Why It’s Vital for Meat Quality and Safety ?

1. Prevents Bacterial Growth

Microbes like Listeria and Salmonella multiply rapidly above -1°C. Blast freezing quickly removes meat from that temperature range, reducing contamination risks.

2. Protects Texture & Juiciness

Slow freezing forms large ice crystals that rupture muscle fibers. Blast freezing forms small crystals that preserve the meat’s structure and moisture.

3. Extends Shelf Life

Faster freezing prevents oxidative changes. Meat frozen properly can be stored up to 12 months with minimal quality loss.

Blast Freezing vs. Conventional Freezing

| Feature | Conventional Freezing | Blast Freezing |

|---|---|---|

| Time to -18°C | 12–24 hours | 2–4 hours |

| Ice Crystal Size | Large (damaging) | Small (minimal damage) |

| Product Yield | Lower (drip loss) | Higher |

| Microbial Safety | Lower | Higher |

| Shelf Life | 3–6 months | 6–12 months |

| Energy Intensity | Moderate | Higher but more efficient |

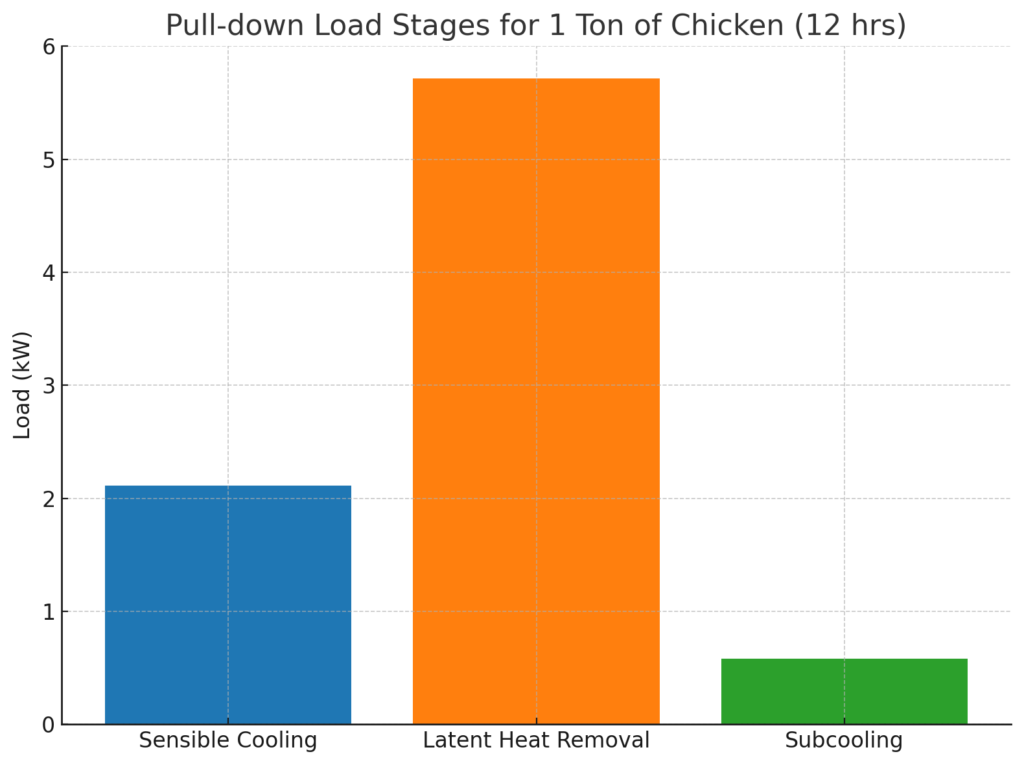

Engineering Insights: Total Heat Load Breakdown

Freezing meat involves three distinct stages of heat removal:

1. Sensible Heat (Before Freezing)

Cooling the meat from its starting temp (e.g., +20°C) to its freezing point (~-1°C)

2. Latent Heat of Freezing

At ~-1°C, meat undergoes phase change—from liquid to solid—without changing temperature.

This is the most energy-intensive phase.

3. Sensible Heat (After Freezing)

Further cooling the frozen meat from -1°C to the final storage temp (typically -18°C)

Example: Freezing 1000 kg of Meat

| Stage | Temp Range | Cp (kJ/kg·K) | ΔT (°C) | Heat Removed (kJ) |

| Sensible (Pre-Freeze) | +20°C → -1°C | 2.8 | 21 | 5,8800 |

| Latent (Freezing Phase) | ~-1°C | – | – | 5,5000 |

| Sensible (Post-Freeze) | -1°C → -18°C | 1.5 | 17 | 2,5500 |

Total Cooling Load: 13,9300 kJ

ASHRAE Guidelines and Design Specs

According to ASHRAE Handbook – Refrigeration:

- Core Temp Goal: -18°C in ≤4 hours

- Surface Temp: Keep below -25°C during freeze

- Air Speed: Minimum 2.5 m/s

- Humidity Control: Maintain RH at 90–95%

- Coil Fin Spacing: 6–8 FPI to reduce frost

System Design: What HVAC Engineers Need to Know

Freezer Types

- Tunnel Freezers – For inline high-throughput

- Spiral Freezers – Compact, continuous operation

- Plate Freezers – Ideal for boxed or cut meat

Airflow Design

- Use CFD simulations to ensure even airflow

- Avoid corners and blind zones

Coil & Defrost

- Use hot gas defrost to minimize downtime

- Wide fin spacing ensures better air movement

Energy Optimization

- Install VFDs on fans

- Use low-GWP refrigerants like NH₃ or CO₂

Common Problems & Quick Fixes

| Problem | Quick Fix |

| Uneven freezing | Add airflow diverters, use CFD modeling |

| Frost buildup | Wide fin spacing, schedule hot gas defrost |

| Dehydration | Maintain RH ≥ 90%, add fogging system |

| Energy spike | Use VFDs, insulate suction lines & ducts |

Role-Based Tips for Professionals

For HVAC Design Engineers

- Simulate airflow early. Poor air balance = uneven freezing

- Slightly oversize coils to reduce frosting cycles

For Plant Managers

- Use wireless temperature loggers for batch-level QA

- Schedule defrosts during product transfer or breaks

For Energy Auditors

- Track kWh per ton of meat frozen weekly

- Look for compressor short cycling – it signals capacity issues

References

- ASHRAE Handbook – Refrigeration

- USDA Freezing Guidelines

FAQ Section

- What is blast freezing? A method of freezing food fast using cold air at high speed, usually around -35°C.

- Why does blast freezing preserve meat better? It forms tiny ice crystals that don’t damage the meat’s cells.

- How long does it take to freeze meat in a blast freezer? Usually under 4 hours to reach -18°C internally.

- Is blast freezing energy-intensive? It can be, but using VFDs and smart controls helps reduce energy use.